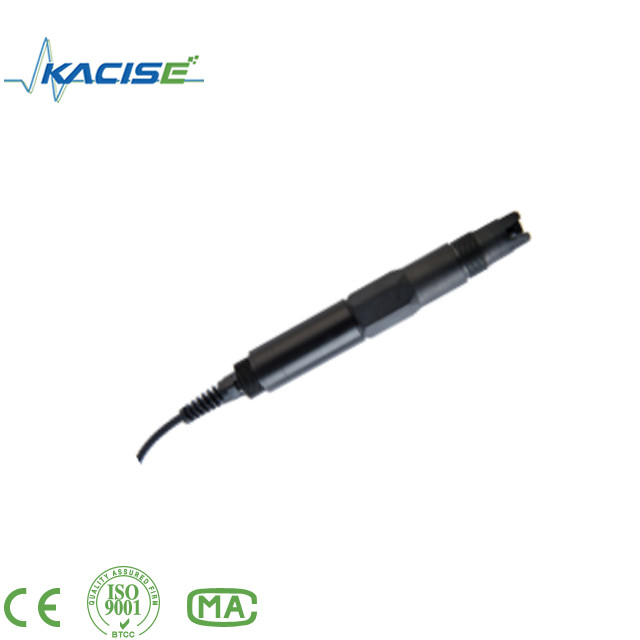

KWS-3000 On-line Residual Chlorine Sensor

1. Applications

Kacise on-line residual chlorine sensor is used to monitor the residual chlorine content continuously in drinking water treatment plant, canning plant, drinking water distribution network, swimming pool, cooling circulating water, water quality treatment project.

2.Technical Specifications

|

Module No.

|

KWS-3000

|

|

Principle

|

the constant voltage method

|

|

Range

|

0~2.000mg/L(HClO)

|

|

Accurate

|

±5% or ±0.05mg/L

|

|

Resolution

|

0.001mg/L

|

|

Calibration Function

|

Two point Calibration (Zero and Slope )

|

|

Temperature Compensation

|

Temperature compensation automatically (Digit temperature sensor)

|

|

Working temperature

|

0 ~ 50℃

|

|

Output

|

Support RS-485, MODBUS protocol

|

|

Power Supply

|

12~24VDC±10%

|

|

Velocity

|

30-60 L/h

|

|

Installation

|

Circulation pool installation

|

|

size

|

30×233mm(Φ×L)

|

|

Protection

|

IP68

|

|

Material

|

Polyacetal resin, PTFE, Gold, Silver

Polyformaldehyde resin, teflon, gold, silver, electro conductive rubber

|

3 Outline

4 Electric Connect

The electrode should be installed closely with the circulation pool. The electrode measurement part should be placed in the area near the circulation pool inlet. It is not allowed to face the outlet. Ensure the smooth flow . We suggest to control the flow rate within 30-60l /h to ensure the test accuracy.

Red: Power supply (12~24V)

Black: Ground(GND)

Blue: 485A

White: 485B

Exposed wire: shielded wire

Please make sure that you connect the wire correctly.

Cable specifications: the cable has a certain corrosion resistance, considering that it has been immersed in water (including seawater) or exposed to air for a long time. The diameter is Φ6 mm. Please make the waterproof processing on cable joint.

5 Maintenance

1) Sensor detection and maintenance

The new electrode and the electrode placed for a long time should be activated before use. The sensor shall be left in the tap water for 24 hours.If the returned value is not correct, please make the following operation.

l Calibration of zero point and slope of electrode

l Returned to the factory for inspection.

2) Calibration of sensors

a) zero point calibration: the sensor probe is placed in chlorine-free water for zero point calibration after the numerical stability.

B) slope calibration: the sensor probe is placed in the flow pool with residual chlorine standard liquid, and the slope calibration is performed after the value is stable. Suggest to use 1-2mg/L HCIO standard solution. About the preparation and determination of the standard liquid, we can refer to the determination of residual chlorine standard.

Note: the sensor has been calibrated before delivery. Since the preparation of its standard liquid has high requirements on personnel, non-professionals may not be qualified for this job. Only if the value is determined to be inaccurate, it is recommended that the user do not calibrate the sensor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!