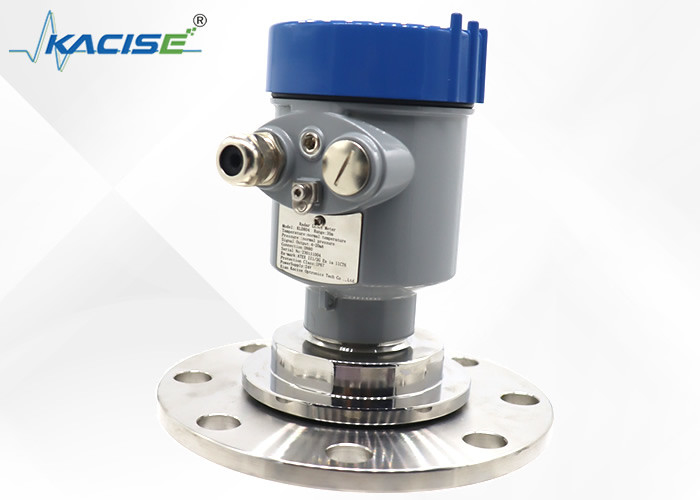

KLD804 4-20mA / RS485 76mm Lens Antenna Radar Level Sensor for Liquid and Solid Medium

Introduction

The 80G lens radar level sensor adopts 80GHz high-frequency radar technology, and focuses the radar waves on the surface of the material through the lens and antenna. When radar waves encounter materials, reflections and scattering occur. The reflected and scattered signals are received through the antenna and receiver, and then converted into material level information.

Compared with the traditional level measurement method, the 80G lens radar level sensor has higher measurement accuracy and wider measurement range. Lens focusing technology can reduce interference and improve signal-to-noise ratio, thereby improving measurement accuracy. The 80GHz high-frequency radar technology can penetrate the dust mist and steam of materials, and is suitable for level measurement in harsh environments such as high temperature, high pressure, flammable and explosive.

Feature

- The measurement accuracy can reach ±2mm.

- The smaller antenna size satisfies the measurement of more working conditions.

- A variety of lens antennas, smaller launch angles, more concentrated energy, stronger echo signals, and higher reliability than other radar products under the same industrial and mining conditions.

- It has stronger penetration and can be used normally in the case of adhesion and condensation.

- The dynamic signal range is larger, and the measurement of low dielectric constant media is more stable.

Specification

| Medium |

strong corrosive liquid, steam, foam |

| Measuring range |

0.1m~10/20/30/60/100m |

| Process connection |

flange ≥ DN50 |

| Process temperature |

-40~130℃ |

| Process pressure |

-0.1~1.0MPa |

| Antenna size |

76mm lens antenna |

| Antenna material |

PTFE |

| Accuracy |

±2mm (range below 35m)

±5mm (range between 35m and 100m)

|

| Protection class |

IP67 |

| Center frequency |

80GHz |

| Launch angle |

3° |

| Power supply |

two-wire /DC24V |

| |

four-wire /DC12~24V |

| |

four-wire /AC220V |

| Casing |

aluminum/stainless steel |

| Signal output |

two-wire: 4...20mA/HART protocol |

| |

four-wire: 4...20mA/ RS485 Modbus |

Product Dimension

Unit in mm:

Installation Method

Flange installation

When using flange installation, the minimum distance between the instrument and the tank

wall should be 200mm.

① datum plane

② vessel center or axis of symmetry

Hoisting Installation

At present, radar level sensors are widely used in many industries, such as metallurgical industry, coal industry, cement industry, petrochemical industry, etc. These industries are subdivided into many specific occasions:

Metallurgical industry

Metallurgical industry applications mainly include iron ore, limestone raw materials, and raw coal bunkers in steel plants; carbon powder, aluminum ore, and coal powder in aluminum plants.

coal industry

The main applications in the coal industry include raw coal, clean coal, cinder, coal powder, and coal-containing sewage in coal washing plants.

Power Industry

The main applications in the power industry include desulfurization, lubricating oil, mud, raw coal bunkers, fuel bunkers, etc.

Water industry

The main applications in the water conservancy industry include lakes, rivers, reservoirs, open channels, wetlands, shoals, tides, underground water pipe networks, ditches containing a large amount of floating matter and sediment, places where a large amount of aquatic plants are produced, and areas where flash floods occur frequently.

Petrochemical industry

The main applications in the petrochemical industry include crude oil, hydrogen tincture, dirty oil, and sludge in oil production plants, settling tanks, sewage tanks, and drilling mud tanks in oil fields, liquefied natural gas, condensed water in liquefied gas stations, oil storage depots, and biodiesel Gasoline, diesel, and tar from the factory, urea melt, ammonia water from the compound fertilizer factory, various chemical products, high-temperature, high-pressure, highly corrosive media, and toxic products from the chemical factory.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!