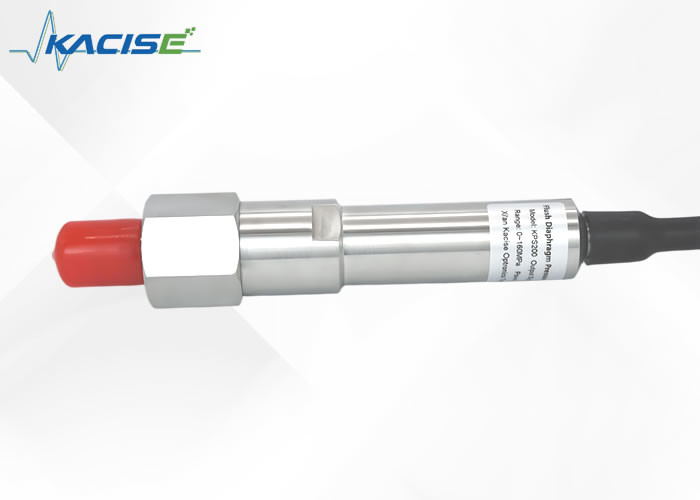

KPS200 Flush Membrane Pressure Transmitter

1.Introduction

The strain gauge high-pressure pressure transmitter is another result of our company's introduction and digestion of foreign product technology. Its measurement range can reach 160Mpa, and it has the characteristics of high response, high precision, solid structure, corrosion resistance, vibration resistance, high performance and high cost performance.

The product is widely used in the petroleum industry, especially for high-pressure measurement of imported mud pumps, fracturing trucks, cementing trucks, etc., and is the preferred transmitter to replace imported products.

This explosion-proof type meets the requirements of GB3836.1-2010 and GB3836.4-2010 standards and has obtained an explosion-proof certificate.

The explosion-proof product is suitable for occasions where explosive gases may appear. The corresponding explosion-proof areas are Zone 1 and Zone 2, and the typical representative gas is propane.

2.Dimension

3.Technical Specifications

| Measuring range |

0~30…160MPa |

| Overload |

1.5 times full scale pressure (maximum 160MPa) |

| Nonlinearity |

±0.5%FS |

| Zero error |

±1%FS |

| Full range error |

±1%FS |

| Insulation resistance |

250Ω@250V DC |

| Operating temperature |

-30~70℃ |

| Explosion-proof type |

-30~60℃ |

| Storage temperature |

-40~70℃ |

| Power supply |

12~28VDC |

| Output signal |

4~20m ADC (Second line) |

| Load resistance |

≤(U-12)/0.02Ω (Second line) |

| Enclosure protection |

IP65 |

| Electrical connection |

Four-core or six-core plug-in |

| Electronic casing |

stainless steel 304 |

| Sensor casing (pressure-sensitive diaphragm) |

stainless steel 17-4PH |

| Seal |

Nitrile rubber, copper pad |

4. Transport, packaging and storage

4.1 Transport

Check whether the instrument has been damaged during transport. If there is obvious damage, please contact us.

4.2 Packaging and storage

Do not remove the packaging before installation.

4.3 Permissible conditions for storage:

Storage temperature: -40~+70 °C

Storage humidity: 45%~75% relative humidity (no condensation)

5. Installation

The pressure sensitive element used in this product transmits pressure through the pressure-sensitive diaphragm. Any touch will cause damage to the transmitter.

▶ Do not touch the inside of the pressure interface in any way.

5.1 Installation preparation

Check that the appearance of the transmitter is good;

The sealing surface of the pressure interface of the transmitter is clean and undamaged;

Consider the applicability of the measured medium;

The ambient temperature and medium temperature must be within the product technical specifications;

There is enough space for safe electrical installation.

5.2 Transmitter installation and sealing method: straight thread, sealing surface uses sealing ring

Installation internal thread:

The transmitter installation internal thread depth must be greater than the thread length.

5.3 Transmitter electrical system

The product matching plug-in is a waterproof plug-in. To ensure the product protection level, be sure to lock the connector during electrical connection.

Power supply: See the product label for details (the power supply must meet the requirements of relevant standards, and the power supply system should be reliable.) The intrinsically safe explosion-proof transmitter is powered by a safety barrier.

Electrical connection requirements: Select a cable with a diameter that matches the plug cable gland, and the cable gland and plug must be intact.

Electrical connection requirements: See the product label for wiring definition

Product pin definition:

Black: Power supply V﹢

Red: Signal output OUT (two-wire system)

6. Disassembly, maintenance, cleaning and repair

6.1 Product disassembly

The transmitter is used in hazardous places such as toxic, harmful, high temperature and high pressure.

▶ Please follow the relevant operating specifications.

▶ Wear necessary protective equipment.

The pressure transmitter needs to be depressurized and powered off, disconnect the electrical connection, and use a wrench to remove it.

6.2 Maintenance

The transmitter does not require maintenance during normal use and is only maintained by the manufacturer.

When using explosion-proof transmitters, improper operation will cause the explosion-proof performance to fail.

▶ Intrinsically safe explosion-proof products are not allowed to replace circuit components or structures to avoid affecting the explosion-proof performance of the product.

6.3 Cleaning

Using the wrong cleaning agent will damage the product label

▶ Do not use irritating cleaning agents.

▶ Do not use harmful or sharp cleaning utensils.

▶ Do not use abrasive rags or sponges.

Use clean water and traditional cleaning agents to clean the product. Before cleaning, the pressure transmitter needs to be depressurized and powered off. Wipe the surface of the transmitter with a soft damp cloth.

6.4 Repair

Residual media can cause personal injury, property damage and environmental damage

The residual media on the disassembled pressure transmitter can cause harm to personnel, environment and equipment.

▶ With hazardous substances, including material safety data of the corresponding media.

When transporting the pressure transmitter, please pay attention to the following points:

All delivered instruments must not contain any hazardous substances (such as acids, alkalis, solutions, etc.) and must be cleaned before returning. When returning the instrument for repair, the original packaging or suitable transport packaging should be used.

6.5 Disposal

Improper handling of the product can cause harm to the environment.

Please dispose of the transmitter components and packaging materials in an environmentally compatible manner and in accordance with national waste disposal regulations.

7. Faults

In the event of any fault in the transmitter, first check whether the transmitter is correctly installed from the pressure connection and electrical connection.

Common faults and solutions are as follows:

| Fault |

Causes |

Solution |

| No output signal |

Cable breakage |

Check the connection |

| Signal exceeds full scale |

Overvoltage limit exceeded |

Observe the permissible overvoltage range |

| Signal error is large |

Ambient temperature exceeded |

Use within the permissible temperature range |

| Pressure changes, output is constant |

Transmitter damage |

Replace the transmitter |

| Signal jump |

EMC interference source on site, such as frequency converter |

Use shielded cable |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!