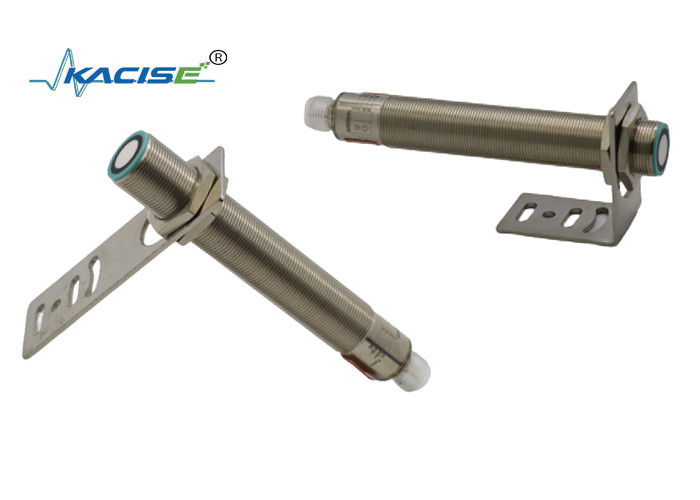

RS485 Output Signal low cost price ultrasonic liquid level meter gauge ultrasonic tank water level sensor

1. Parameter

General specifications

| Sensing range |

100... 1000 mm |

| Unusable area |

0 ... 100 mm |

| Standard target plate |

100 mm x 100 mm |

| Transducer frequency |

approx.220 kHz |

| Response delay |

approx. 50 ms |

Indicators/operating means

| LED blue |

power-on |

|

LED yellow

|

indication of the switching state

flashing: program function object detected

|

|

LED red

|

permanently red: Error Red,flashing:program function,object not detected |

Electrical specifications

| Operating voltage UB |

15 ... 30 V DC , ripple 10 %SS |

| No-load supply current I0 |

≤ 45 mA |

Input

| Input type |

1 TEACH-IN input |

|

operating range A1: -UB ... +1 V, operating range A2: +6 V ...+UB

|

| input impedance: > 4.7 kΩ ; TEACH-IN program pulse: ≥ 1 s |

Output

| Output type |

1 switch output E4, NPN NO/NC,programmable |

| Rated operating current Ie |

200 mA , short-circuit/overload protected |

| Default setting |

Switching point A1:70mm Switching point A2: 800mm |

| Voltage drop |

≤ 2.5 V |

| Repeat accuracy |

≤1 % |

| Switching frequency f |

≤ 13 Hz |

| Range hysteresis H |

2 % of the set operating distance |

| Temperature influence |

±1.5% of full-scale value |

Ambient conditions

| Ambient temperature |

-25…70℃(248...343K) |

| Storage temperature |

-40…85℃(233...358K) |

Mechanical specifications

| Connection |

V1 connector(M12×1),4-pin |

| Protection degree |

IP67 |

| Material Housing |

brass, nickel-plated |

| Transducer |

epoxy resin/hollow glass sphere mixture;

foam polyurethane, cover PBT

|

2. Dimensions

3. Electronic interface and signals definition

4. Description of Sensor Functions

Adjust the paramater

The ultrasonic sensor features a switch output with two teachable switching points. These are set by applying the supply voltage - UB or + UB to the TEACH-IN input. The supply voltage must be applied to the TEACH-IN input for at least 1 s.LEDs indicate whether the sensor has recognised the target during the TEACH-IN procedure. Switching point A1 is taught with - UB,A2 with +UB. Eight different output functions can be set.

Switching point, Setting distance only after power on. The internal clock can assure can't be changed after 5 mins when power on. If want to change the switching point, the user can only setting the request distance after power restart.

TEACH-IN window mode, normally-open function

- Set target to near switching point

- TEACH-IN switching point A1 with - UB

- Set target to far switching point

- TEACH-IN switching point A2 with + UB

TEACH-IN window mode, normally-closed function

- Set target to far switching point

- TEACH-IN switching point A2 with - UB

- Set target to near switching point

- TEACH-IN switching point A1 with + UB

TEACH-IN switching point, normally-open function

- Set target to near switching point

- TEACH-IN switching point A1 with - UB

- Cover sensor with hand or remove all objects

from sensing range

-TEACH-IN switching point A2 with + UB

TEACH-IN switching point, normally-closed function

- Cover sensor with hand or remove all

objects from sensing range

- TEACH-IN switching point A2 with - UB

- Set target to near switching point

- TEACH-IN switching point A1 with + UB

TEAC-IN large hysteresis interval, normally-open mode

- Set target to near switching point

- TEACH-IN switching point A1 with + UB

- Set target to far switching point

- TEACH-IN switching point A2 with - UB

TEAC-IN large hysteresis interval, normally-closed mode

- Set target to far switching point

- TEACH-IN switching point A2 with + UB

- Set target to near switching point

- TEACH-IN switching point A1 with - UB

TEACH-IN detection of objects presence normally open mode

- Cover sensor with hand or remove all objects from

sensing range

- TEACH-IN switching point A2 with - UB

- Cover sensor with hand or remove all objects from

sensing range

- TEACH-IN switching point A2 with + UB

TEACH-IN detection of objects presence normally closed mode

- Cover sensor with hand or remove all objects from sensing range

- TEACH-IN switching point A2 with +UB

- Cover sensor with hand or remove all objects from sensing range

- TEACH-IN switching point A2 with -UB

Default setting of switching point

A1=blind range,A2=nominal distance

| LED displays |

| Displays in dependence on operating mode |

Red LED |

Yellow LED |

|

TEACH-IN switching point

Object detected

No object detected

Object uncertain(TEACH-IN invalid)

|

off flashes On

|

flashes off

off

|

| Normal operation |

off |

Switching state |

| Fault |

on |

Previous state |

5. Installation conditions

If the sensor is installed at the environment temperature fall below 0℃,It should do well on the protective measures. In case of direct mounting of the sensor in a through hole using the steel nuts, it has to be fixed at the middle of the housing thread.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!