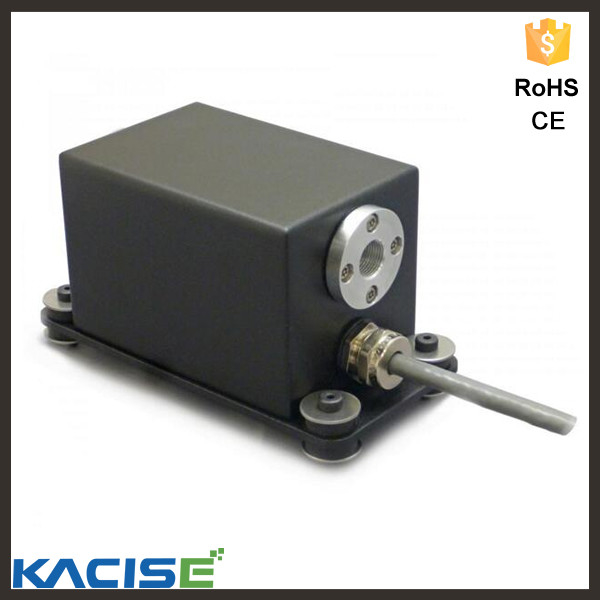

DC-1 Electromagnetic metal abrasive fluid sensor Instructions

Wear debris eaton sensor high quality low price

Description

Mechanical equipment fault occurs are mostly caused due to mechanical wear, wear particles exist in a large amount of information about wear condition, the monitoring can be used to judge the wear state or judgment occurred in the form of wear and tear. When the damage is going to happen, the number of metal particles in the lubricating oil will increase dramatically. Diameter of the metal particles will increase, according to the cumulative total number of detected metal particles, can be given key indicators: whether there is a fault, when it should be shut down, you can also run long, to prevent secondary damage, effectively reduce repair costs, reduce the cut-off time interval, so that the loss caused by interruption is minimized.

Metal CHECK sensor is a real time monitoring system of oil particles, inline of the oil pipeline, and 100% of the metal particles detected by the system, combined with the use of monitoring software, Metal CHECK oil pipeline may wear metal particles number of accumulating statistics, and the number of particles per unit of time by the trend analysis. Metal CHECK industrial, marine and aerospace has been widely used. The sensor uses electromagnetic induction to detect the number of the lubrication system of the metal particles, as determined extent of bearing or gearbox damage by data. The sensor must be installed before the filter, the lowest point in the return line position. Each detected a metal particle, particle sensors automatically accumulates count, and regularly sends up position this time period to detect the total number of particles.

Wiring diagram

Features

l Easy to install

l Robust design

l Full flow design

l No moving parts

l Online, real-time detection

l 5KV high isolation voltage signal line

l Intuitive results of the monitoring data

l Transmission distance up to a maximum 1km

l 100% detection of ferrous and non-ferrous metal particles

Specification

Spec. |

Sensor diameter | Min particle | Min flow | Max measure rate |

Iron | Non-Iron |

8mm | 125μm | 450μm | ≥0.5 L/min | 65 1/s |

Power supply |

Power | 12VDC~33 VDC @5W (Max) (300 mA @ 24 VDC) |

Oil pressure | ≤20 bar (300 psi) |

Oil Temp. | -40°C ~ 85°C |

Ambient Temp. | -40°C ~ 70°C |

Medium | Hydraulic and lubricating oils; synthetic oils and mineral oils etc. |

Output signal |

Communication mode | RS485 Half Duplex |

Isolation voltage | 5kV |

Data transmission | Time to send the cumulative number of particles within the time period |

| | | | | | |

Dimension

Work environment

Working environment |

Humidity | Relative humidity 20%~85% work, no condensation; storage humidity 98% |

Weight | < 0.6 kg |

Oil pressure | < 20 bar (300 psi) |

Ambient Temp. | -40°C~70°C |

Operating Temp. | -40°C~85°C |

Medium | Hydraulic, lubricating oils, synthetic, mineral oils etc. |

Electrical connection

|

No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

Name | NC | NC | 485GND | 485 - | 485 + | Power+ | Power- | NC |

Color | | | Brown | Red | Grey | White | Black | |

Installation

Note: oil must be made through the sensor before passing through the filter.

1. Oil pipe to pass through the sensor before passing through the filter, so the detection is effe

2. The sensor is fixed through the bottom bracket of the sensor, and the sensor is connected with the oil return line.

3. Select the installation position should avoid strong magnetic power, large vibration occasions.

System installation

- 1. Install DC-1 sensor for equipment.

- 2. Install DC-1 PC software.

- 3. In the monitoring terminal using the RS485-RS232 converter the RS485 signal is converted to RS232, the signal is sent to the computer.

- 4. Every 10min, the monitoring software will display a set of current particle cumulation.

Packing list

List |

No. | Name | number | tagging |

1 | DC-1 sensor | 1 | |

2 | 5 pin shielded cable | 10m | |

3 | Power adapter | 1 | |

4 | CD | 1 | Software |

5 | O type circle | 2 | |

6 | Fixed support | 1 | Matching |

7 | DC-1 manual | 1 | |

Company Profile

Xi'an Kacise Optronics Co., Ltd. was founded in 2000, is located in Xi'an, Shaanxi Province, China, is a professional engaged in instrumentation and sensors, R & D, production, sales as one of professional high-tech enterprises, we have our own production workshop and central laboratory. Factory building area is about 3000 square meters, with production of more than 30 employees, 8 engineer, 6 inspectors, 10 saleman, 5 for customer service, is this industry, we are one of the strong technology manufacturers with varieties specification.

When the company set up, we began to focus on the coordination of military supplies production, achieved GB/T19001-2008/ISQ9001:2008, GJB 9001B-2009 certification. When our company is running mature and stable, in 2008, we began to develop our business. Based on the production of military products quality control, we developed a lot of sensor products, such as a load cell and pressure sensor. We have the key technology and development center of advanced sensors, and we cooperation with Northwestern Polytechnical University, Xi'an Jiao Tong University and other colleges and universities. Product quality is the life of enterprise, customer demand is our existence!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!